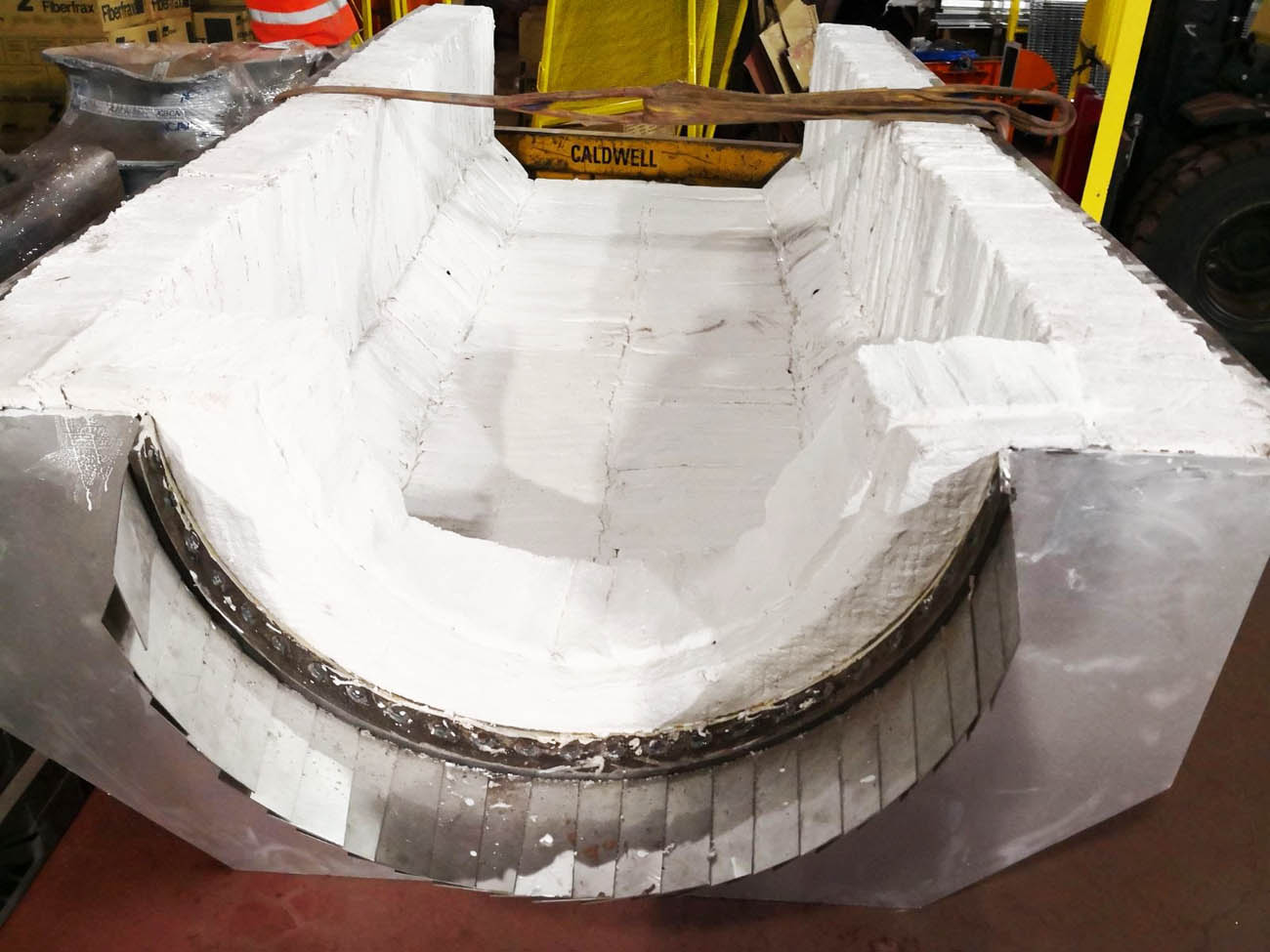

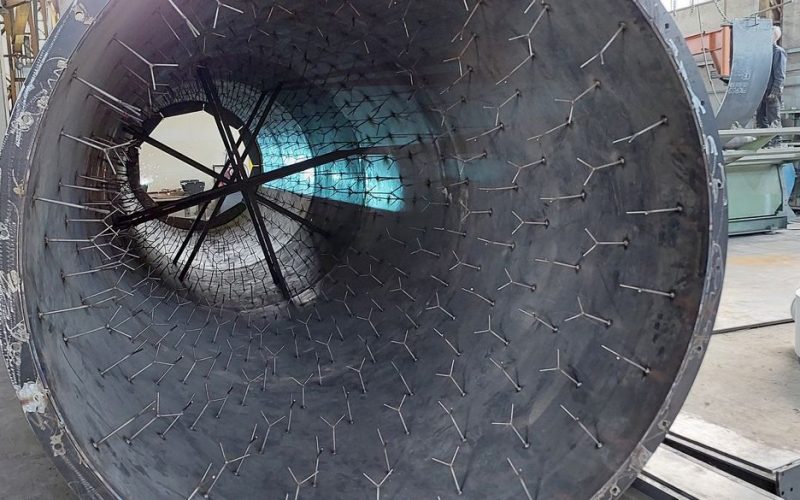

In a direct-fired rotary kiln, the heat is pushed through the interior of the kiln, meaning the heat transfer comes from the direct contact between the heat source and the material. Due to the high heat being pushed through the kiln, this kind of rotary kiln is refractory lined, usually with a brick or castable lining, which protects the steel shell from the high internal temperatures. This kind of rotary kiln is a robust and efficient unit for heat transfer and pyroprocessing.

Quick contact info

Complete the fields below to send a message to our Customer Service. We will answer as quickly as possible.